Manufacture from aguamiel or maguey sap

Process of obtaining agave syrup

Blue Weber agave plant (Agave tequilana) in the foreground. Agave cones (plant without leaves, as harvested), in the background

What is agave syrup?

Agave syrup is a sweetener, similar in appearance to honey, although less dense, which is obtained from plants of the Agave genus, called maguey. They are plants native to Mexico: their sap is rich in fructans, and is used for the production of the famous drinks tequila and mezcal.

Of all the agaves, the most cultivated is the blue Weber agave or tequila agava (Agave tequilana Weber.), because it has the sweetest flavor.

Agave sap (maguey) and aguamiel

Agave sap is rich in fructans: inulin and FOS (fructooligosaccharides). They are polysaccharides formed by long chains of fructose linked to a glucose.

Inulin and FOS cannot be assimilated; they are a soluble fiber with a prebiotic effect.

Fresh agave has to go through a series of processes to break all the inulin chains, releasing its sugars: mainly fructose, and to a lesser extent, sucrose and glucose.

After a refining process, agave syrup is obtained, which will have a very high fructose content and will have lost all the agave fiber.

On the other hand, agave inulin can also be found on the market, an excellent prebiotic due to its richness in inulin and FOS (fructooligosaccharides), fibers that promote the proliferation of a healthy, fermentative intestinal microbiota.

Aguamiel, a hydrating and prebiotic drink, is extracted from some species of Agave. Pulque is made from this beverage.

Harvesting maguey to obtain agave syrupe

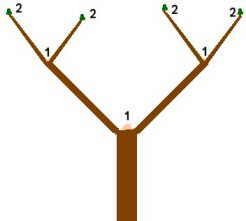

– Maguey, the agave plant, is generally planted during Lent, when it produces the sweetest the heart of the plant (or agave pines) (piñas de agave in Spanish).

– It is harvested before flowering, when agave pinneaples are ripe and have a higher sugar concentration.

– For harvesting, the maguey leaves are cut, leaving only the stalk or inner part. Then the plants are cut from the base and shaved to leave the heart of the maguey plant ready, obtaining a very characteristic appearance, the so-called agave pines.

– Inside the agave pines (metzontete or mezontete), which have a hard shell, is the sap of the agave plant.

Agave syrup: Processed and refined

Agave processing is carried out in factories. First, the agave hearts or agave pinneaples are cut into pieces, which consists of splitting them into quarters or halves, depending on their original size.

Agave syrup can be obtained in two ways: by enzymatic processes or by thermal hydrolysis (by heat). In both processes, the same thing happens chemically: the inulin chains are hydrolyzed (broken) and broken down into sugar (mainly fructose, and to a lesser extent, sucrose and glucose).

Characteristics of agave syrup

Agave syrup that can be found in stores is a sugar-saturated product. It contains 99.5% sugar (sugars in the form of fructose).

Agave syrup provides the same calories as table sugar, but with a lower glycemic index. It has the same contraindications as fructose.

Black agave syrup is less processed and has lower sugar content (77%).

Agave curiosities

Traditional production of Agave beverages

The process of transforming agave into a sugar-rich juice is nothing new. This process has been carried out since ancient times in the production of mezcal, a traditional Mexican drink.

This process released the sugars from the agave for the subsequent production of fermented beverages.

According to tradition, after harvesting, the agave hearts (agave pines) were heated in stone ovens. The traditional agave beverage production process was as follows:

– Firewood was placed at the base and set on fire. Stones were then placed on top of the firewood until they were heated. A layer of wet bagasse was then added on top of the stones, which would help to evenly distribute the heat and prevent the agave pines from burning or becoming too raw.

– To bake the agave pines, they were cut into halves or quarters and placed on top of the bagasse layer to heat them in the stone oven.

– During baking, it was covered with leaves of different vegetables, which would impart a characteristic aroma to the final result, and then with soil. Preventing oxygen from passing through helped prevent the agave hearts from burning.

– It took between three and four days for the agave hearts to cook. The heat from this process transformed inulin (fiber) into sugar (fructose).

The heat from this process converted inulin (fiber) into sugar (fructose). These sugars are susceptible to fermentation, which is useful for the production of alcoholic beverages.

Generally, this baking process is used for the production of mezcal or tequila. The final aroma of the beverage would depend in part on the oils released by the plants used in combustion during baking.

Baked agave or maguey pines according to the traditional process of obtaining mezcal

Grinding and obtaining sweet agave juice

After baking, the agave pines are ground (grinding). Traditionally, grinding is done in wooden vats. The juice obtained is quite fibrous.

The residue left over from the juice extraction is called “bagazo de agave” (agave bagasse), and is a product rich in insoluble fibers, mainly cellulose, lignin and hemicellulose. The possible use of these fibers, which are a waste product of the agave beverage industry (tequila and mezcal), is currently being studied. For example, they could be used to produce renewable energy or building materials.

The following image corresponds to the grinding of agave in a stone mill, pulled by an animal. This procedure corresponds to the traditional production of mezcal. You can appreciate the fibrous and juicy texture of the agave or maguey pulp:

Agave or maguey pulp in a vat for grinding, in a traditional mezcal production factory. The ground agave (previously baked) can be seen, with a fibrous or filamentous and juicy texture.

To obtain fermented beverages, such as mezcal, water was then added, followed by fermentation, distillation of the must, refining and packaging.

![]() More information on properties of agave syrup and its contraindications

More information on properties of agave syrup and its contraindications